AHLM: Helping harness the potential of real-time insights from construction sites

Over the last 60 years, Bröderna Ahlm has been the market leader in construction machinery and methods in Scandinavia.

Ahlm is the pioneer of the aptly named ’Ahlm method’, which is a line of machines specialized for the distribution and application of self-leveling concrete at construction sites. The machines transport the dry mix, adding water on-site to initiate the process—it’s essentially a mobile, self-leveling concrete factory. As the pump trucks distribute dry mix, instead of wet concrete, they can service multiple projects in a single workday.

The Challenge

Each pump truck is equipped with a PLC (Programmable Logical Controlling unit) that allows the operator to process overviews, control the truck’s operations, access settings, get measurements, undertake mixing management, print reports, etc.

This means each truck has a plethora of real-time data generated through IoT devices. However, the truck reports were being stored as raw data in several locations, and Ahlm was not able to utilize this in the most optimal manner, holding back value from them and their customers.

Objectives

- Create a centralized repository of real-time data.

- Deliver relevant insights to their clients on the progress of their projects at construction sites.

- Establish an easy mechanism for customers to sign off on pump truck deliveries on site.

- Harness the potential of real-time data from sites to market the scale of their operations.

Development

Villvay devised a hybrid app which works on both web and mobile to help Ahlm meet its objectives. The app was developed using Python, React, and Java Spring Boot, and is hosted on Google Cloud.

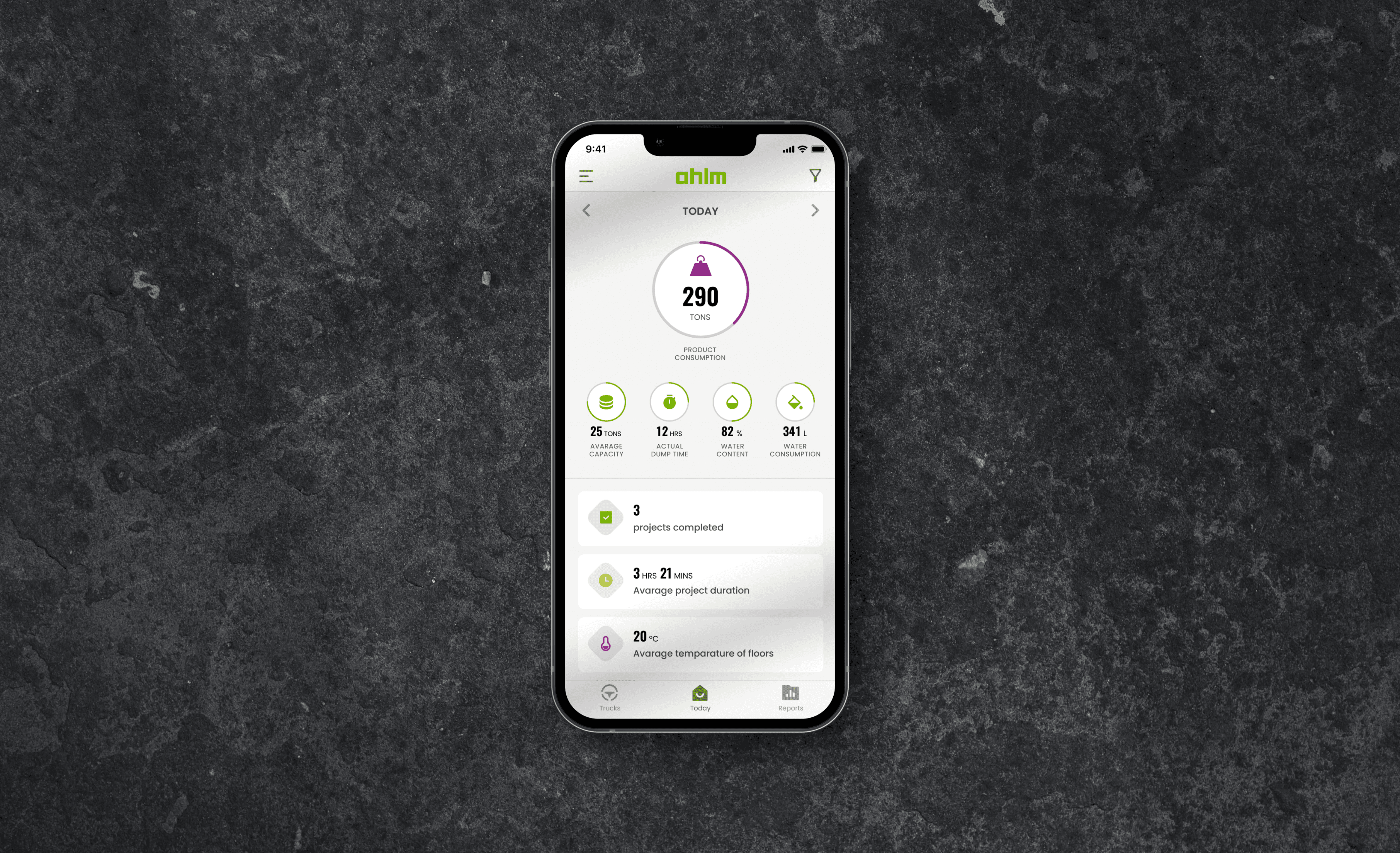

Tackling the issue of raw data from the trucks, we worked on visualizing the data, creating a client dashboard. This visual dashboard provided project information such as:

- The amount of water used

- Pump times

- Temperature and capacity,

along with generating customs reports

This dashboard was made available to clients via multilingual web and mobile apps with individual logins.

In addition to client portals, Ahlm itself required a centralized mechanism to easily connect pump truck data to its back office teams for inventory and billing purposes. An admin dashboard was developed that let users add, remove and edit pump truck schedules and customer requirements, along with generating tokens for each truck.

With Ahlm and their customers covered, the focus was now on potential customers. Villvay developed a public dashboard accessible as a web app that collated real-time information from all pump trucks. This was able to reveal general statistics to anyone who visited the site without the need to log in—the ideal preview of what was in store.

The Results

- - Customers were able to track and review information on their respective projects and sign off on all transactions digitally, all of which was stored on the cloud. Previously, this was a manual, time-consuming activity with a lot of room for error with misplaced information.

- - Better customer relationships through transparency and real-time updates.

- - More than 100 pump trucks generating more than 1000 custom reports for more than 1000 projects.